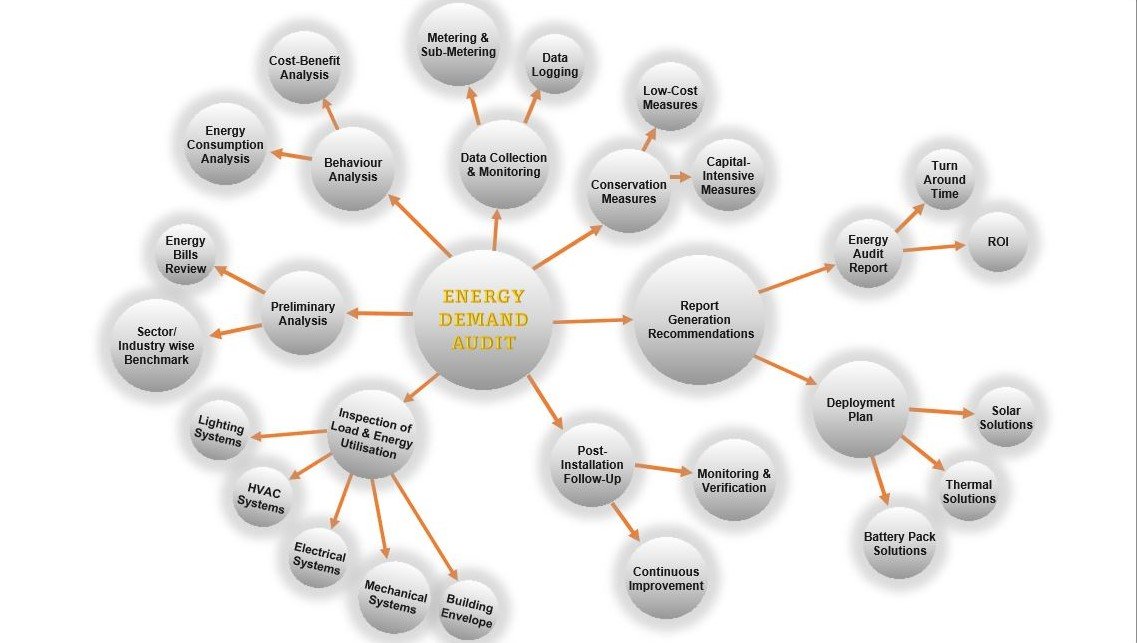

Energy demand audit

An energy demand audit is a comprehensive assessment of energy consumption within a facility, building, or system. Its primary goal is to identify areas of inefficiency and opportunities for energy conservation and cost savings. Here’s an overview of the typical steps involved in conducting an energy demand audit:

Gathering Information: Collect data on energy consumption, including utility bills, equipment specifications, operating schedules, and occupancy patterns. This data provides a baseline for understanding current energy usage.

Site Inspection: Physically inspect the facility to identify energy-related equipment, systems, and processes. This may include HVAC systems, lighting, appliances, insulation, and windows.

Analysis of Energy Use: Analyze energy usage patterns to identify trends and anomalies. Look for peak demand periods, excessive consumption, and areas of potential waste.

Energy Modeling: Use computer modeling software to simulate energy usage under different scenarios and identify potential energy-saving measures. This may include upgrading equipment, optimizing schedules, or implementing energy-efficient technologies.

Identifying Opportunities: Based on the analysis, identify specific opportunities for energy conservation and cost savings. This may include low-cost measures such as weather-stripping and caulking, as well as larger investments like upgrading to energy-efficient appliances or installing renewable energy systems.

Cost-Benefit Analysis: Evaluate the costs and benefits of each potential energy-saving measure. Consider factors such as upfront investment, energy savings, maintenance costs, and return on investment (ROI).

Recommendations: Develop a detailed report outlining recommended energy-saving measures, along with estimated costs, savings potential, and implementation timelines. Prioritize recommendations based on their feasibility and potential impact.

Implementation Plan: Develop a plan for implementing the recommended energy-saving measures, including budgeting, scheduling, and resource allocation. Consider engaging stakeholders and obtaining buy-in from decision-makers.

Monitoring and Verification: After implementation, monitor energy usage to verify the effectiveness of the measures. Compare actual energy savings to initial projections and make adjustments as needed.

Continuous Improvement: Energy demand audits are not a one-time event. Continuously monitor energy usage and identify additional opportunities for improvement over time.